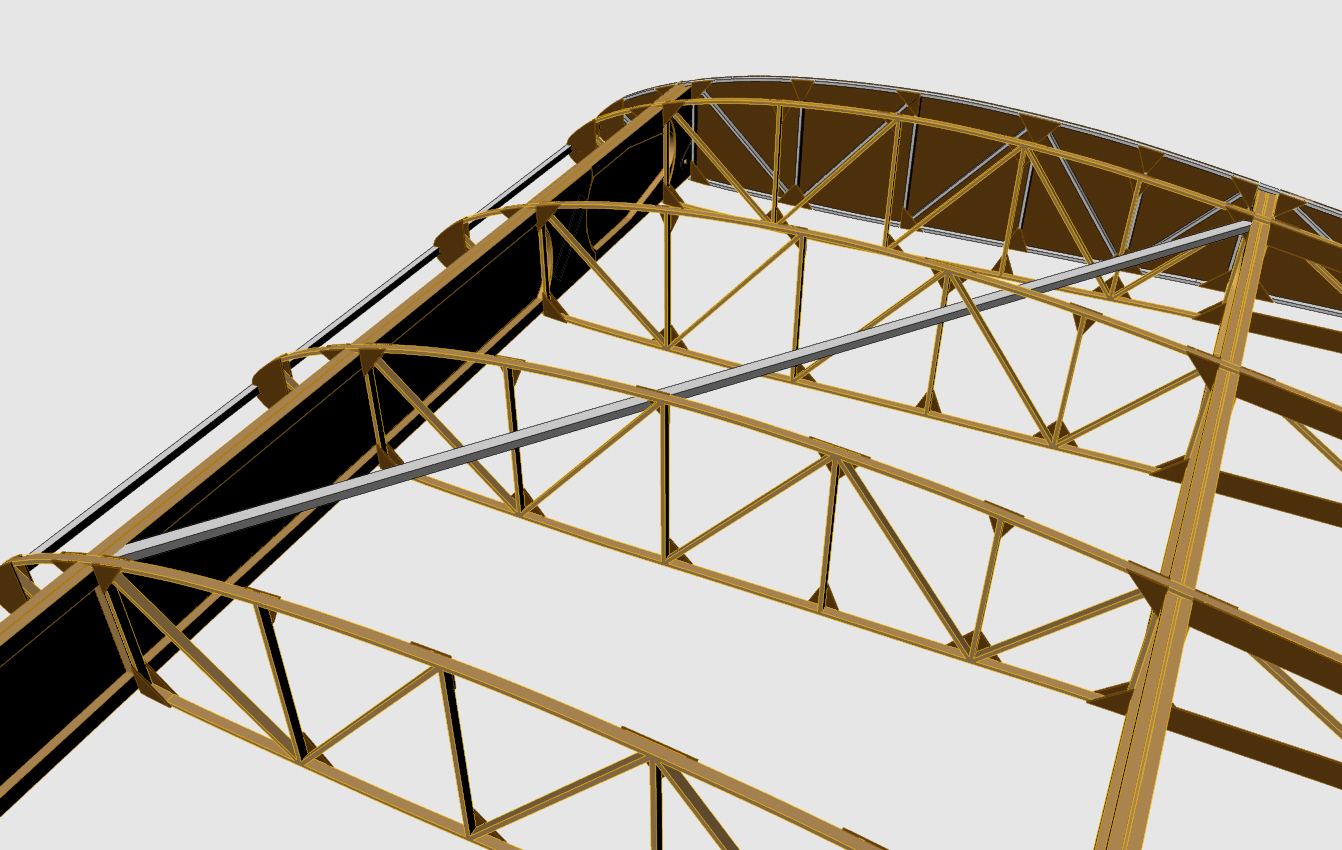

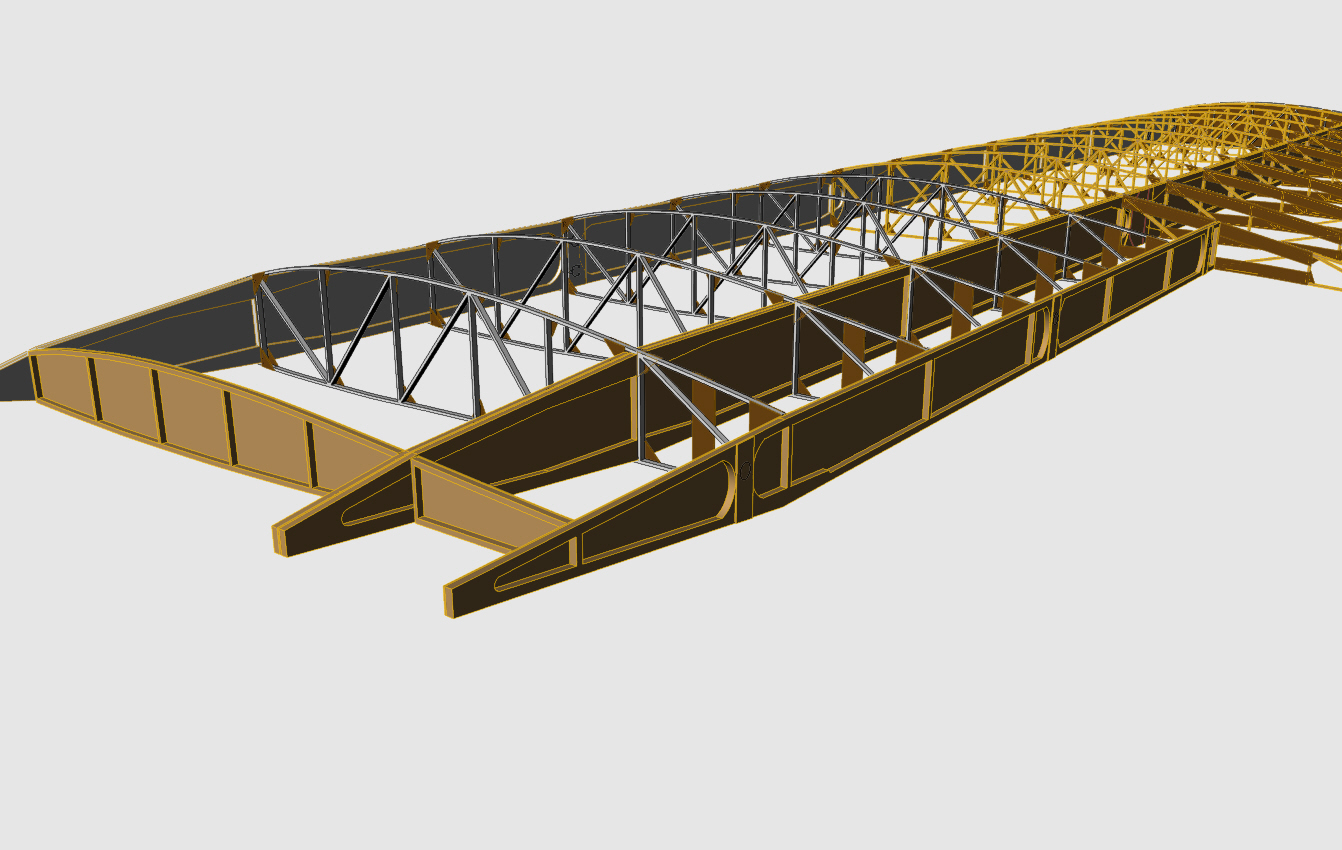

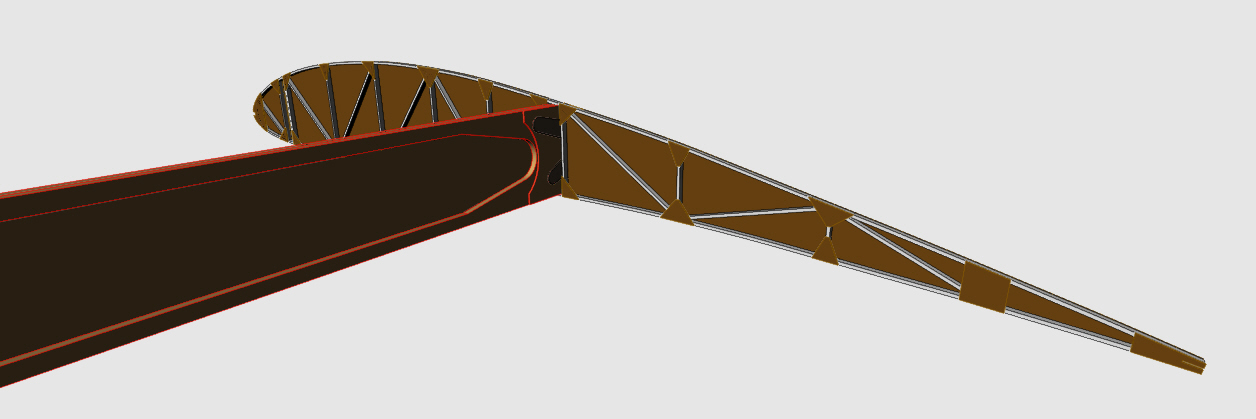

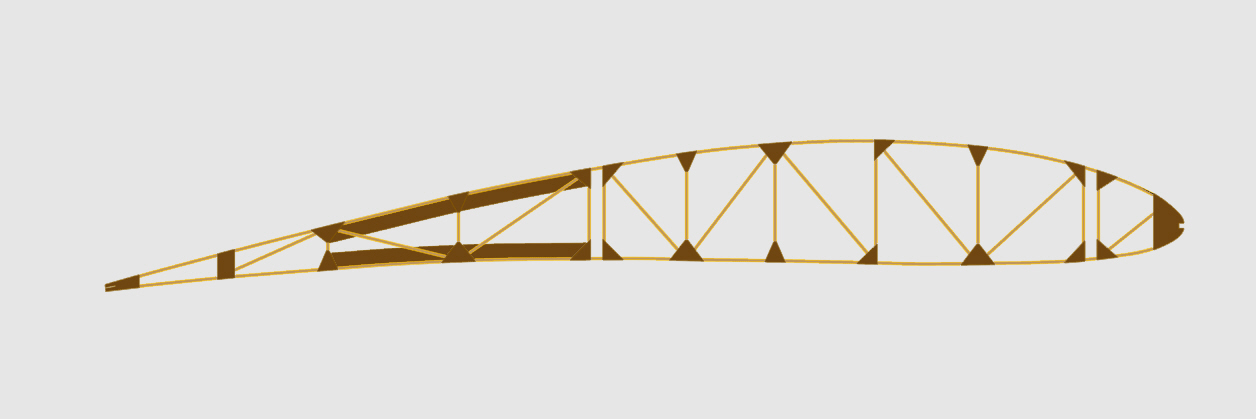

The first part to be designed is the rib. I’m saying „the rib“ because there is just one. This one design is used in different configurations throughout the whole wing. So starting here has a few benefits. The part is pretty straight forward. It will be cut from a single piece of 1mm cardboard. The corner and edge enforcements are 1,5mm spruce on the original. These will be cut from regular 160gr/m² paper/card.

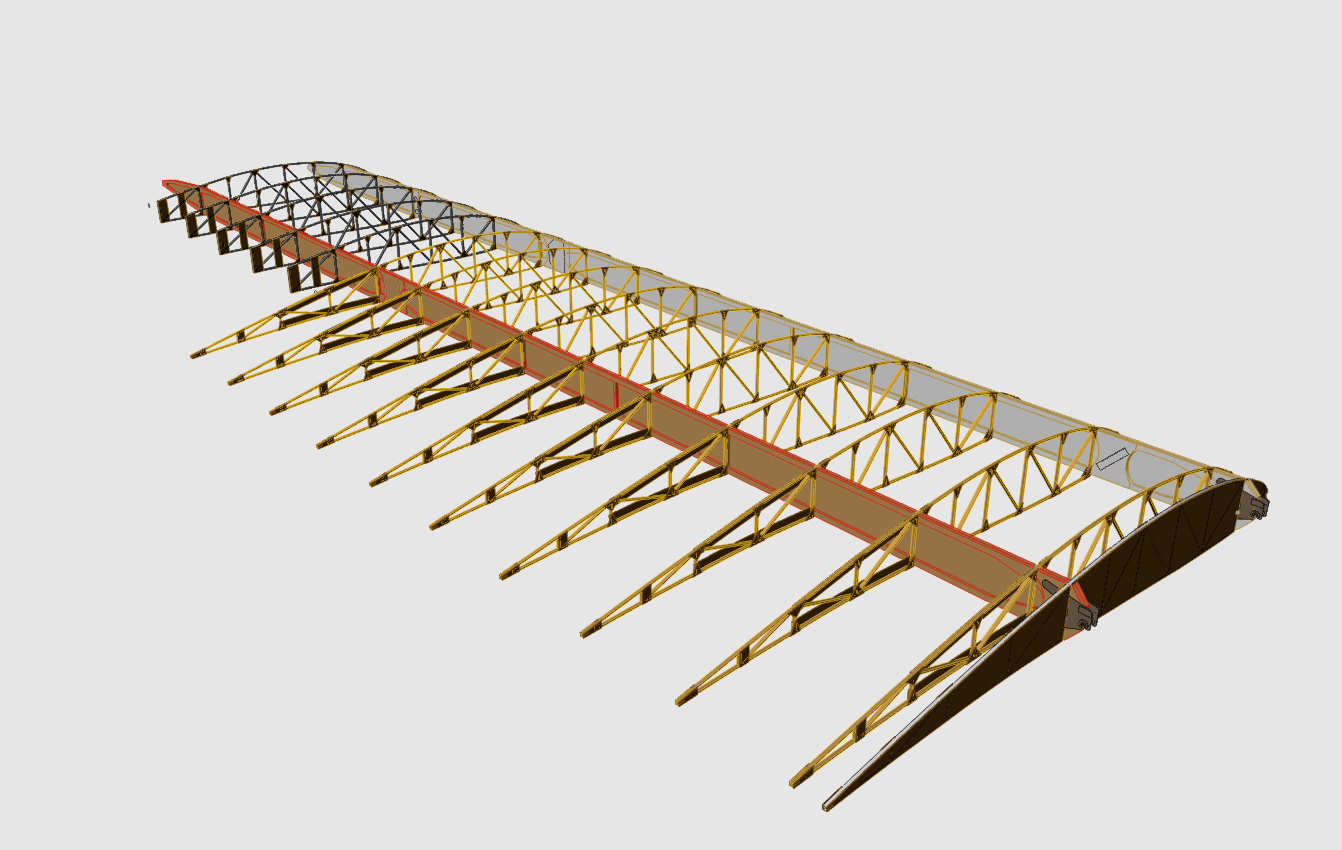

Thinking of cutting: Maybe it is not needed to have the corner enforcement and all the other parts in this thickness cut by laser. I might design it to be cut by hand with a clever layout for cutting efficiency. Or I might acquire a cutting plotter like the a Silhouette Cameo by Graphtec. This is a small desktop cutter which should be suitable for a smaller project.

I am also thinking about a layout which makes it quick and easy to position all the parts in one step. Like glueing the rip structure to the enforcment parts which are still in the paper frame and cutting everything afterwards (I think I might need an image to explain that). This would save me from having to number all the parts indiviually.